Label Hotel

Label storage with just-in-time delivery

The solution handles retail packing, carton labeling, and pallet labeling.

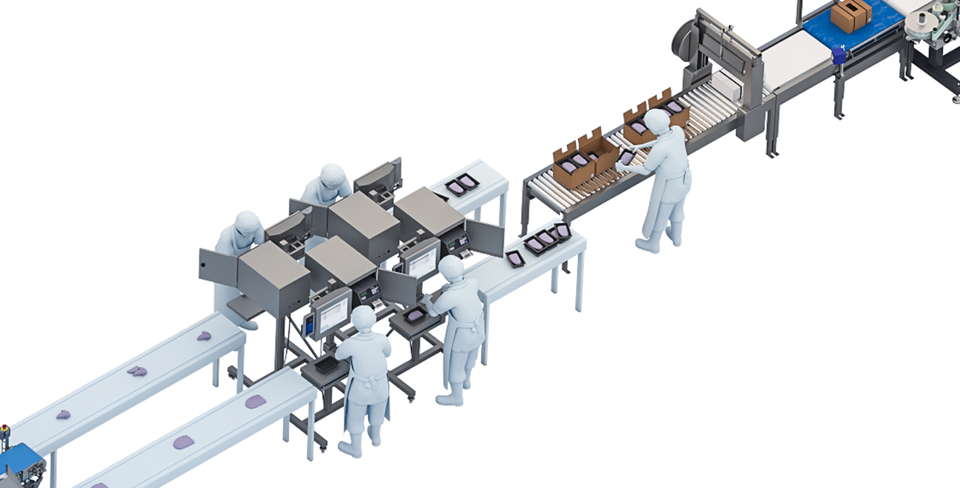

The Multiple Packing Line system can accommodate several manual packing stations that can be activated as needed. For example, if five different products need to be packed simultaneously, five packing stations are staffed; if only two products need packing, just two stations are used. This makes the system a flexible solution that is easy and quick to adjust to varying production demands.

The solution consists of a conveyor system for moving retail products, two, three, or more manual packing stations equipped with scales and printers, a carton labeling station, and a pallet labeling station.

On the conveyor system, for example, three different retail products pass by three manual packing stations. The operator at packing station 1 is dedicated to packing product A only, the operator at station 2 handles product B, and the operator at station 3 manages product C.

Each operator takes “their” retail product from the conveyor belt, weighs it, packs it into a plastic tray, prints and applies the product label, and then sends the tray further along the conveyor.

Using a photoelectric sensor at each packing station, the MPL system detects which station the plastic tray came from, thereby identifying the product in the tray. When the tray reaches the carton labeling station, a carton label with the correct product description is printed and automatically applied to the tray.

The tray then continues along the line, is packed onto pallets, which are then sent to the pallet labeling station, where the correct label is automatically printed and applied to the pallet.

Benefits

The solution delivers improvements including:

- Rapid product changeover

- Automatic product identification

- Accurate labeling

- Scalable system

- Packing of different products on the same line

- Automatic carton labeling

The solution handles retail packing, carton labeling, and pallet labeling.

The Multiple Packing Line system can accommodate several manual packing stations that can be activated as needed: if five different products need to be packed simultaneously, five packing stations are staffed; if only two products require packing, just two stations are used. This makes the system a flexible solution that is easy and quick to adjust to varying production demands.

The line consists of a conveyor system for transporting retail products, two, three, or more manual packing stations equipped with scales and printers, a carton labeling station, and a pallet labeling station.

For example, the conveyor system moves three different retail products past three manual packing stations. The operator at packing station 1 is dedicated solely to packing product A, the operator at station 2 only packs product B, and the operator at station 3 handles product C.

Benefits

The solution offers improvements including:

- Rapid product changeover

- Automatic product identification

- Accurate labeling

- Scalable system

- Packing of multiple products on the same line

- Automatic carton labeling

The solution manages retail packing, carton labeling, and pallet labeling.

The Multiple Packing Line system can accommodate several manual packing stations that can be activated as needed. If five different products need to be packed simultaneously, five packing stations are staffed; if only two products require packing, just two stations are utilized. This makes the system a flexible solution that is easy and quick to adjust for varying production demands.

The line consists of a conveyor system for transporting retail products, two, three, or more manual packing stations equipped with scales and printers, a carton labeling station, and a pallet labeling station. For example, the conveyor system moves three different retail products past three manual packing stations. The operator at packing station 1 is dedicated solely to packing product A, the operator at packing station 2 handles only product B, and the operator at packing station 3 is responsible for product C.

Read more about the related products in the solution here:

Meet our Label experts

Have a question? Request a Callback

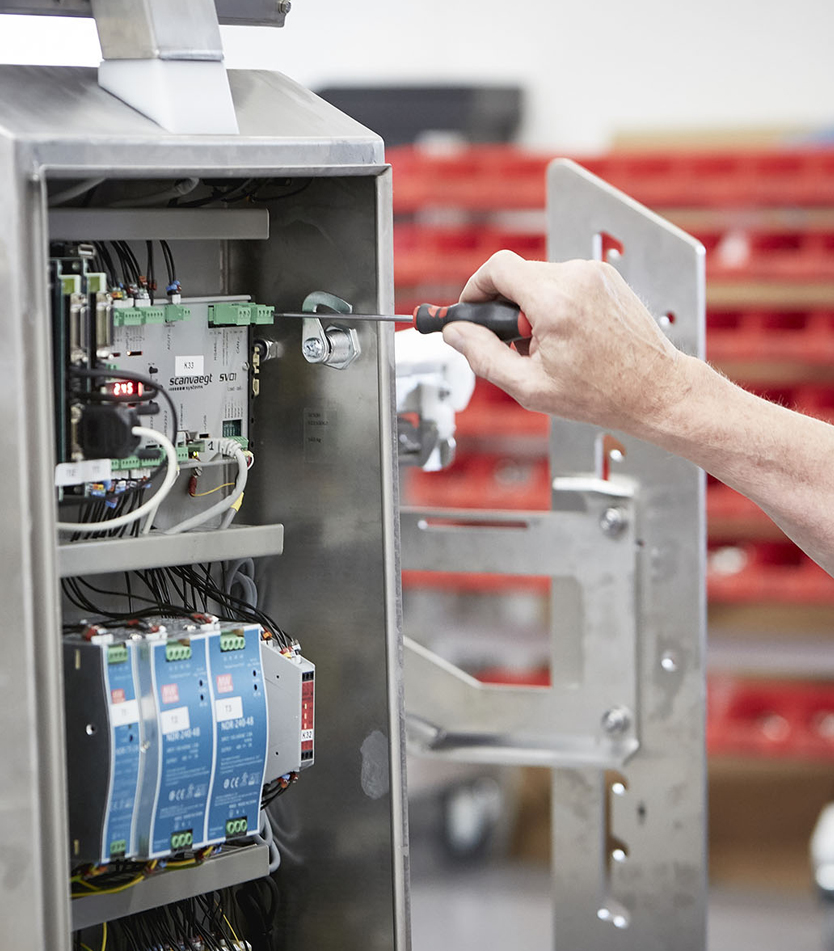

ScanCare Service – Ensures High Operational Reliability

Operational reliability is crucial for business efficiency and, consequently, profitability. Scanvaegt Service offers preventive maintenance and urgent “first aid” services that optimize the operational reliability and uptime of your equipment, allowing you to focus on running your business.

With a ScanCare Service Agreement, you have comprehensive service and support facilities at your disposal to ensure optimal operation and uptime of your business equipment.